A synchro is an electromagnetic transducer commonly used to convert angular position of shaft into an electrical signal.It is commercially known as a selsyn or an autosyn.It basically consists of a synchro transmitter (generator) and a synchro receiver(control transformer).

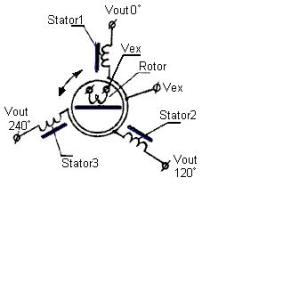

Schematic of Synchro Transducer The complete circle represents the rotor. The solid bars represent the cores of the windings next to them. Power to the rotor is connected by slip rings and brushes, represented by the circles at the ends of the rotor winding. As shown, the rotor induces equal voltages in the 120° and 240° windings, and no voltage in the 0° winding. [Vex] does not necessarily need to be connected to the common lead of the stator star windings.

A synchro or “selsyn” is a type of rotary electrical transformer that is used for measuring the angle of a rotating machine such as anantenna platform. In its general physical construction, it is much like an electric motor . The primary winding of the transformer, fixed to the rotor, is excited by a sinusoidal electric current (AC), which by electromagnetic induction causes currents to flow in three star-connected secondary windings fixed at 120 degrees to each other on the stator. The relative magnitudes of secondary currents are measured and used to determine the angle of the rotor relative to the stator, or the currents can be used to directly drive a receiver synchro that will rotate in unison with the synchro transmitter. In the latter case, the whole device (in some applications) is also called a selsyn (a portmanteau of self and synchronizing).

stepper motor

There are two distinctly different ways of using stepper motors in control systems.One is the open loop mode and other is the closed loop mode.

The stepper motor is a digital device whose output in shaft angular displacement is completely determined by the number of input pulses.Consequently,there is no need for a feedback device to determine the position of motor shaft and ,therefore,of the load connected to the motor shaft.We can use an open step servo system with the same accuracy as that of a closed loop analog system.

The relation between a synchro and stepper motor is that the stepper motor is just a special type of the synchro. A stepper motor is designed to rotate through a specific angle (called a step) for each electrical pulse received from its control unit.

If we need to operate the stepper motor in closed loop(positional feedback)mode,we need to use synchros for error operate a gate controlling the pulses from a pulse generator